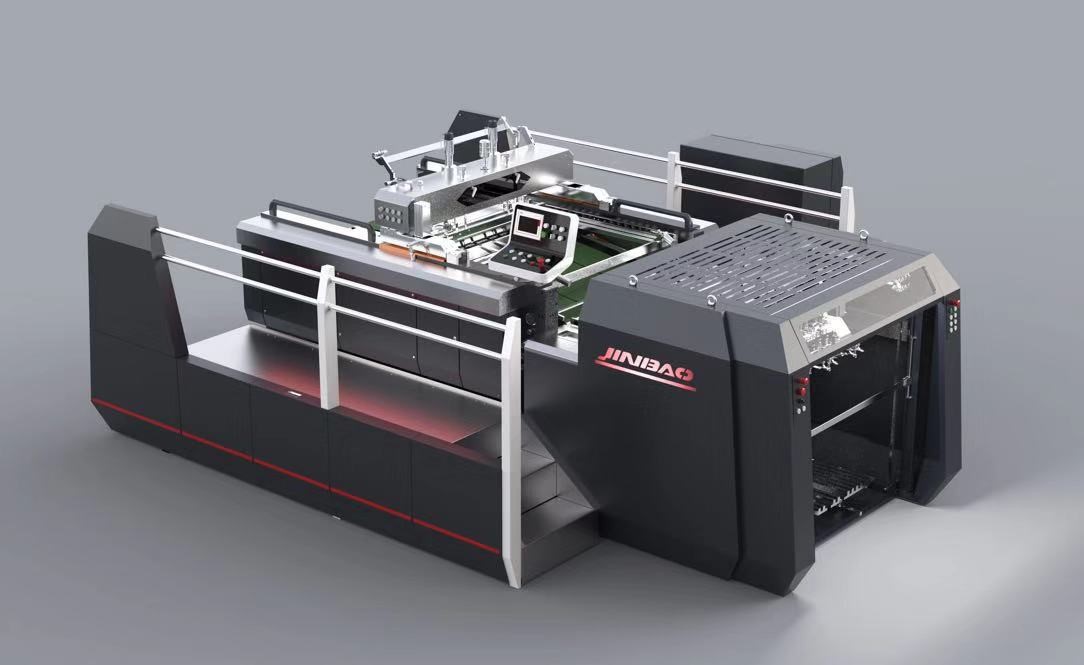

I-JB-106AS Servo Motor Controlled Automatic Stop Cylinder Screen Cindezela

| JB-106AS | |

| Ubukhulu. usayizi weshidi | 1060×750㎜² |

| Okuncane. usayizi weshidi | 560×350㎜²can |

| Ubukhulu. usayizi wokuphrinta | 1050×750㎜² |

| Usayizi wozimele | 1300×1170 mm² |

| Ubukhulu beshidi | 80-500 g/m² |

| Umngcele | ≤10mm |

| Isivinini sokuphrinta | 800-5000ishidi/h |

| Amandla okufaka | 3P 380V 50Hz 24.3Kw |

| Isisindo esiphelele | 4600㎏ |

| Usayizi uwonke | 4850×4220×2050 mm |

1. Isiphakeli sephepha: i-offset Feida ikhanda, isivinini esiphezulu, ukwethembeka nokuzinza.

Inokuvumelana nezimo okuqinile kubukhulu bezingxenye eziphrintiwe, futhi iqinisekisa ukudla okubushelelezi kwephepha ngesivinini esikhulu;

I-feeder yephepha ingazikhethela yona futhi ishintshe ishidi elilodwa noma iphepha eline-laminated ngenkinobho eyodwa.

2. Ithebula lokuphakela amaphepha:

Itafula lokuphakela ngensimbi engagqwali lingavimbela ngempumelelo ingemuva le-substrate ukuthi lingaklwebheki, futhi linciphise ukungqubuzana okumile phakathi kwetafula ne-substrate;

Nge-vacuum adsorption phansi kwetafula, ngesakhiwo sokusunduza iphepha kanye nephepha lokucindezela etafuleni, ukuqinisekisa ukuthuthwa okubushelelezi kwezinto ezihlukahlukene;

Uma kudla ishidi elilodwa lephepha, ibhande lokuthutha linciphisa ijubane ngesikhathi esifanele ukuze kuqinisekiswe ukuthi i-substrate izinzile futhi isendaweni ngesivinini esikhulu.

3. Igeji eseceleni ye-pneumatic:

Igeji yokudonsa ehlangothini yokudonsa edonsayo ebheke phansi ngeke ibangele amaphepha amhlophe nangcolile kanye namamaki ombhalo;

Uhlobo olulodwa lwe-push gauge oluguquguqukayo lomzimba, inkinobho eyodwa yokhiye, ukuqala nokulawula ukuguqulwa kwe-push gauge pull gauge;

I-Push pull positioning inembile, i-stroke yokumisa yinde, isivinini sokuma siyashesha, futhi ukulungiswa kulungele. Isistimu yokuthola ugesi wesithombe ingaqapha ukuma kwezingxenye eziphrintiwe ngesikhathi sangempela futhi inciphise izinga lokunyathelisa imfucuza.

4. Uhlelo lwe-Shaftless: umthombo wamandla owodwa wendabuko wedrayivu eyinhloko enamamodi amaningi okushayela

Kusetshenziswa ubuchwepheshe be-synchronous drive, i-transmission shaft, i-gearbox nezinye izinsimbi ziyasuswa, bese kusetshenziswa ama-servo motors amaningi ukulandela i-virtual electronic spindle. Inani elikhulu lezingxenye zokudlulisela ngomshini zisusiwe.

Ukuncishiswa komsindo: i-shaft eyinhloko yendabuko kanye nebhokisi legiya kuyalahlwa, izingxenye ezihambayo ziyancishiswa, ukwakheka komshini kwenziwa lula, futhi izakhi ezikhiqiza ukudlidliza komshini ziyancishiswa, ngakho-ke umsindo uyancipha kakhulu ohlelweni lokusebenza.

5. Uhlelo olunzima lwe-pneumatic scraping: ukusetshenziswa okuphelele kobuchwepheshe kagesi, i-pneumatic, i-hydraulic, ukulawula okuzenzakalelayo kwesenzo sokukhuhla;

Amaphuzu okuqala nawokugcina angasethwa ngokuzimela;

Yonke inqubo yokucindezela ilinganisela futhi izinzile;

Ngemva kokugaya i-scraper noma ukufaka esikhundleni esisha, cindezela ukhiye owodwa ukuze usethe futhi ubuyisele isikhundla sokucindezela ukuphrinta kwangaphambilini;

Iqeda ngokuphelele ukungalungi kwe-cam mechanical control of squeegee action, futhi iqinisekisa ukuthi ungqimba lukayinki nokucaca kwesithombe kuzinzile ngaphansi kwanoma iyiphi ivolumu yokunyathelisa nesivinini sokunyathelisa.

6. Umsebenzi wokuhlukanisa isikrini:

Isikrini sihlukaniswe ukulawula kagesi ukuze kuvezwe lonke ithebula lokudlulisa kanye ne-roller, ukuze kube lula ukubhaliswa kwezingxenye zokunyathelisa kanye nokulungiswa kwezinto zokudla; ngesikhathi esifanayo, ukuhlanzwa kwe-roller nesikrini kuphephile futhi kushesha;

7. Isistimu yokulungisa kahle isikrini sikagesi, isikrini esikude sikagesi sokulungiswa kwe-axis emithathu, ukushaywa okuqondile kokufakwayo kokufakwayo, ukulungiswa kwesinyathelo esisodwa endaweni, okulula futhi okusebenzayo.

8. Isistimu yokugcoba amafutha neyokugcoba ngokuzenzakalelayo inganciphisa ukudonsa kwamaketanga nomsindo, futhi iqinisekise ukunemba nokusebenza nokuzinza.

| Into | Isiyalezo | |||

| 1 | Umphakeli |

| ||

|

| ● | Ikhanda lesiphakeli senguqulo ye-offset yangemuva | Abane abamunca ukulethwa okune, ngokulungiswa kwe-pre-position | ejwayelekile |

| ● | Imodi yokuphakela iphepha yemodi ekabili | ishidi elilodwa (ukuphakelwa kwephepha eliguquguqukayo) noma ukugqagqana (ukuphakelwa kwephepha okulinganayo) | ejwayelekile | |

| ● | Ukushintsha okusheshayo kwemodi yokuphakela iphepha | ukushintsha ukhiye owodwa | ejwayelekile | |

| ● | Ukutholwa kabili kwe-Photoelectric | ejwayelekile | ||

| ● | Ukutholwa kweshidi elikabili nge-ultrasonic | ingasetshenziswa kuphela kwimodi yokuphakela iphepha elilodwa | ngokuzikhethela | |

| ● | Isihluthulelo esisodwa sokushintsha usayizi wephepha | ikhanda le-feeder kanye ne-side gauge stop paper endaweni ngokushesha nangokuzenzakalelayo | ejwayelekile | |

| ● | Ukuphepha kukhawulelwe ekuphakamiseni okuphakelayo | ejwayelekile | ||

| ● | Ukucushwa okujwayelekile kwesistimu engami | ejwayelekile | ||

| ● | Ukulayisha ngaphambilini | nqwabelanisa izinto zokuphrinta kusengaphambili, nciphisa isikhathi sokupakisha futhi uthuthukise ukusebenza kahle komsebenzi | ngokuzikhethela | |

| ● | Idivayisi yokuqeda ugesi omile | inganciphisa ugesi omile endaweni ebonakalayo futhi ithuthukise umphumela wokuphrinta | ngokuzikhethela | |

| ● | ukutholwa kwe-photoelectric yokushoda kwephepha kwetafula lokuphakela iphepha | ejwayelekile | ||

| 2 | Ukudlulisa amaphepha nokuqondanisa ngaphambili-beka kanye ne-side-lay |

| ||

|

| ● | uhlelo lokudlulisa iphepha nge-vacuum | ejwayelekile | |

| ● | igeji yokudonsa umoya ezinhlangothini ezimbili eziya phansi | ukugwema ukudonsa phambili kwephepha. | Okujwayelekile | |

| ● | I-push gauge esemaceleni amabili | ukuphrinta iphepha eliwugqinsi | Okujwayelekile | |

| ● | donsa i-gauge / i-push gauge switch | inkinobho eyodwa yokhiye | Okujwayelekile | |

| ● | iphepha endaweni yokuthola ugesi wezithombe | igeji eseceleni ekutholeni indawo kanye negeji yangaphambili ekutholeni indawo | Okujwayelekile | |

| ● | Isihluthulelo esisodwa sokushintsha usayizi wephepha; ukhiye owodwa wokusetha ngaphambilini | i-side gauge / feed brush wheel ngokushesha futhi ngokuzenzakalelayo endaweni | Okujwayelekile | |

| 3 | Isilinda sokuphrinta |

| ||

|

| ● | Uhlobo lozimele isakhiwo serola esingasindi | Inertia encane, ukusebenza okuzinzile | Okujwayelekile |

| ● | i-adsorption printing kanye nedivaysi yokukhumula evunguzayo | Okujwayelekile | ||

| ● | idivayisi ye-anti rebound yephepha eliwugqinsi | Okujwayelekile | ||

| 4 | Uhlaka Lokuphrinta |

| ||

|

| ● | Ukulungiswa kahle kwesikrini sikagesi sezindlela ezintathu | Ukulungiswa kwezindlela ezintathu kwesikrini esikude sikagesi | Okujwayelekile |

| ● | Ukulinganisa kwepuleti lokuphrinta elingami nelivundlile | Okujwayelekile | ||

| ● | isinxephezelo esizenzakalelayo sokuncipha kobude nokunwetshwa | Isinxephezelo esizenzakalelayo soshintsho lobude beshidi oludalwe inqubo yokuphrinta yangaphambilini | Okujwayelekile | |

| ● | idivayisi yokukhiya i-pneumatic | Okujwayelekile | ||

| ● | ifreyimu ihamba ngokuzimela futhi ayihlanganisi kudivayisi | Okujwayelekile | ||

| 5 | Uhlelo lommese wokuphrinta we-pneumatic |

| ||

|

| ● | Ukucindezela okungaguquki okuzenzakalelayo nokulungiswa okuzenzakalelayo kommese wokunyathelisa | Gcina ingcindezi yokuphrinta ingashintshi futhi uthuthukise ikhwalithi yokuphrinta | Okujwayelekile |

| ● | Ukugoqa okusheshayo nokuzenzakalelayo kommese wokuphrinta nommese obuyayo oyinki | Amandla okubamba ummese wokuphrinta alinganayo, okulula ukufaka esikhundleni sommese wokuphrinta (squeegee) | Okujwayelekile | |

| ● | ohlakaniphile ephakamisa naphansi | Ngokwemibandela yokuphrinta, setha indawo yommese / ummese, unwebe impilo ye-raber scraper kanye ne-mesh, futhi unciphise imfucuza ye-inki. | Okujwayelekile | |

| ● | idivayisi yokulahla uyinki | Okujwayelekile | ||

| 6 | Abanye |

| ||

|

| ● | uhlelo lokuphakamisa umoya webhodi lephepha | Okujwayelekile | |

| ● | uhlelo lokuthambisa oluzenzakalelayo | Okujwayelekile | ||

| ● | isikrini sokuthinta isilawuli somshini womuntu | Okujwayelekile | ||

| ● | i-grating yokuvikela ukuphepha | Khulisa isici sokuphepha ukuze uqinisekise ukuphepha komuntu siqu kwabaqhubi | ukukhetha | |

| ● | unogada | Khulisa isici sokuphepha futhi unciphise umthelela wothuli Ekuphrinteni | ukukhetha | |