I-XT-D Series yomshini wokupakisha we-flexo wokuphrinta wejubane eliphezulu

Zonke izinto zikagesi zomshini wonke zenziwe ngemikhiqizo edumile yamazwe ngamazwe, enekhwalithi ezinzile futhi enokwethenjelwa.

Isixhumi esibonakalayo somshini womuntu, ukuphathwa kwe-oda lekhompiyutha, ukusebenza okulula nokushintsha kwe-oda ngokushesha.

Okokusebenza kungagcinwa ukude ngenethiwekhi, ukuze kwahlulele futhi kuxazululwe iphutha lemishini ngokushesha, kuthuthukiswe ukusebenza kahle kokulungisa nokunciphisa izindleko zokuyilungisa.

Wonke umshini uklanywe futhi wakhiwe ngokuvumelana nokusebenza okuphezulu nokuphepha okuphezulu futhi wonke umshini uhambisana nezinga le-European CE.

I-baffle kanye nezingxenye ezibalulekile zomshini wonke zonke ziphathwa ngokuguga kanye nokushisa ukuze kuqedwe ukucindezeleka kwangaphakathi kwensimbi.

Ifekthri yensimbi ikhiqize ngokuvumelana nencwadi yethu kadokotela.Izinto ezingavuthiwe yi-XN-Y15MnP,HRC 40-45,Amandla e-Tensile yi-450-630, amandla okukhiqiza angaphezu kuka-325.Ingaqinisekisa ukuthi amaphaneli awawoli ngisho nomshini osebenza nsuku zonke.

Zonke zigaywe yi-CNC.Sinemishini engu-8 yama-PC CNC.

Wonke ama-axles omshini kanye nama-roller enziwe ngensimbi yekhwalithi ephezulu, i-tereded, i-quenching kanye nokwelashwa kokushisa;Ukugaya, ukulungiswa kwebhalansi eguqukayo yekhompuyutha enembayo ephezulu, i-chrome eqinile ebekwe phezulu.

Wonke amagiya okuhambisa umshini enziwe ngensimbi yekhwalithi ephezulu, i-carburizing, ukwelashwa kokucisha kanye nokwelashwa kokugaya ukuze kuqinisekiswe ukuphrinta okunembayo okuphezulu kokusebenza isikhathi eside.

1.Material: 20CrMnTi ingxubevange steel, carburized, Cime futhi emhlabathini.

Ukunemba kwe-2.Level 6, ukusebenza kahle, umsindo ophansi, ubulukhuni be-HRC58-62, impilo ende yesevisi, akukho ukugqokwa phakathi neminyaka eyi-10, ukubhaliswa kokuphrinta isikhathi eside kungafinyelelwa.

Ingxenye yokudlulisela (uxhumano lwezinyo le-shaft) yomshini wonke ithatha uxhumano olungenakhiye (i-sleeve yokunweba) ukuze kuqedwe imvume ehlangene yokuxhuma, efanelekile ukusebenza kwesikhathi eside ngesivinini esikhulu nge-torque enkulu.

I-spray lubrication .Iyunithi ngayinye ifakwe idivayisi yokulinganisa uwoyela ukuze kuqinisekiswe ibhalansi kawoyela ethangini likawoyela leyunithi ngayinye.Ibhere lomshini wonke linendawo yokugcwalisa, kulula ukuyigcwalisa.

Izingxenye eziyinhloko zokudlulisa umshini wonke ziyizinsimbi eziziqondanisa eziqinisiwe, ezinempilo ende yesevisi, ukugcinwa okulula nokunemba okuphezulu kugcina imishini isebenza ngesivinini esikhulu isikhathi eside.

Injini eyinhloko isebenzisa injini yokuguqula imvamisa, isilawuli sokuguqula imvamisa, ukonga amandla, isiqalo esizinzile, nedivayisi yokuvikela ukuqala kwemoto.

Idivayisi yokucubungula isithombe esiyingqayizivele, phambi komshini ingabuka umsebenzi wangemuva, ukuze umise ukudla kwephepha uma kunesimo esiphuthumayo, ukunciphisa imfucuza.

Isibani senkomba yesimo esisha, esibonisa isimo sokuqala somshini (ngesimo sebha yenqubekelaphambili yekhompyutha), okubonisa isimo sokusebenza somshini, okubonisa ulwazi lwephutha lomshini.

Iyunithi yomshini wonke ingahlukanisa okuzenzakalelayo okukodwa ngenkinobho eyodwa.

I-SFC shaft ifakwe, (I-Straight Full Chromate), iqine kakhulu, ibushelelezi ayigqwali.

.Ubulukhuni:HRC60°±2°;Ukuqina Ukuqina:0.8-3mm;Ukuqina Kobuso:Ra0.10μm~Ra0.35μm

Umnyango wokulawula ikhompuyutha

· Umshini nezinto zikagesi zonke zenziwe ngemikhiqizo eyaziwayo: isikrini sokuthinta (isikhombimsebenzisi somshini womuntu).

· Ukwenza uziro komshini, isikhundla esisethiwe kanye nemisebenzi yokuqondisa ipuleti okuzenzakalelayo: ukuphrinta, ukumisa isigaba sokubeka uziro nokusetha kusengaphambili ukuze kuqinisekiswe ukuthi konke ukuphrinta ebhodini lokuqala kunoyinki, futhi ibhodi lesibili lilungiswa ngokuyisisekelo endaweni, elingakhokhela amaphutha phakathi nokusebenza.

· Umsebenzi wokusetha kabusha inkumbulo: lapho ipuleti lokuphrinta lidinga ukulungiswa noma ukwesulwa, lo msebenzi ungasetshenziswa.Ngemva kokukhanda noma ukusula, izosethwa kabusha ngokuzenzakalelayo ngaphandle kokulungiswa.

· Oda umsebenzi wesigaba sokugcina: izigaba ze-oda ezingama-999 zingagcinwa.Ngemuva kwe-oda eligciniwe, imishini ibamba ngekhanda ngokuzenzakalelayo indawo yesigaba sepuleti lokuphrinta.Lapho ngokuzayo i-oda eligciniwe lisebenza, ngemuva kokulengiswa kwepuleti, okokusebenza kuzozilungisa ngokuzenzakalelayo endaweni efanele yenkumbulo, okusindisa kakhulu isikhathi sokulungiswa sokushintsha i-oda.

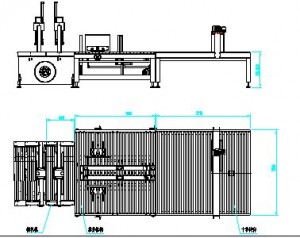

| Into | Iyunithi | 1226 isitayela |

| Ububanzi bangaphakathi be-baffles | mm | 2800 |

| Usayizi weshidi | mm | 1270×2600 |

| Ukuphrinta okusebenzayo | mm | 1200×2400 |

| Usayizi omncane womshini | mm | 320×640 |

| Ubukhulu bepuleti lokuphrinta | mm | 7.2 |

| Isivinini sokusebenza | amashidi/min | 0 -180 |

| Amandla emoto amakhulu | KW | 15 - 30 |

| Amandla aphelele | KW | 35; 45 |

| Isisindo | T | ≈20.5 |

| Ukunemba okuphezulu | mm | ±0.5 |

| Ukunemba kwe-slotting | mm | ± 1.5 |

1.Ngokuvumelana nezimo ezihlukene zokugoba ze-paperboard, ivolumu yomoya ingashintshwa ukuze kuqinisekiswe ukutholakala kwephepha elibushelelezi.

2.Ingemuva lomshini lifakwe i-interlock control switch ukulawula ukuphakelwa kwephepha lokumisa izimo eziphuthumayo.

3.Isilawuli se-Servo sisetshenziselwa ukulawula ukuphakelwa kwephepha nokumisa ukuphakelwa kwamaphepha, okushesha futhi okonga abasebenzi.

4.Yamukela i-servo enegunya lobunikazi elingenalo i-servo ehamba phambili enqenqemeni lokuphakela iphepha lokudla (imigqa emine yamasondo okuphakela iphepha, umugqa ngamunye wamasondo okuphakela amaphepha afakwe injini ye-servo ukuyishayela ngokuhlukana, futhi ngesikhathi esifanayo, iqala futhi ime izikhathi ezahlukene ukuze uthole ukudla okunwetshiwe kwephepha).Ayikho into eyisicaba ebhodini likathayela, okuthuthukisa kakhulu ukucindezelwa kwebhokisi.

5.Izikhundla zama-baffles ohlangothini lwesobunxele nakwesokudla kanye namabhokisi okumisa emuva alungiswa ngogesi;igebe phakathi kwama-baffles angaphambili lilungiswa ngesandla.

I-6.Septum feeder (ukuphakela okuqhubekayo noma kwe-septum kungakhethwa njengoba kudingeka).

7.Ikhawunta yokondla, isetha futhi ibonise inani lokukhiqiza.

2. Idivayisi yokususa uthuli:

I-1.Ibhulashi lengxenye yokuphakela iphepha kanye nedivayisi yokudonsa umoya ephezulu kanye nedivayisi yokususa uthuli ingasusa kakhulu ukungcola endaweni yokunyathelisa yephepha lephepha futhi ithuthukise ikhwalithi yokunyathelisa.

3, I-roller yokondla amaphepha:

1.Irola ephezulu: Ububanzi obungaphandle yipayipi lensimbi elingu-87mm eliwugqinsi, lifakwe izindandatho ezimbili zokuphakela amaphepha.

2.Irola ephansi: Ububanzi bangaphandle ¢ 112mm ipayipi lensimbi eliwugqinsi, indawo engaphezulu igaywe futhi i-chrome eqinile icwecwe.

3.Igebe legebe lamarola wokuphakela amaphepha lilungiswa mathupha, ngobubanzi obungu-0-12mm.

4, Idivayisi ye-zeroing ezenzakalelayo:

1.Ukuphakela, ukuphrinta kanye ne-slotting kusethwa kabusha ngokuzenzakalelayo kube yiqanda.

2.Amabhokisi ajwayelekile asebenzisa idivayisi ye-zeroing ezenzakalelayo, zama ukuphrinta kabili kungalungiswa endaweni efanele, ukunciphisa udoti wekhadibhodi.

II.Umnyango Wokuphrinta((Inketho yokuqala -iyunithi yemibala eyisithupha)

1. Irola yokuphrinta (i-Plate roller)

1.Ububanzi bangaphandle ¢ 405.6mm (kuhlanganise nobubanzi bepuleti langaphandle ¢ 420mm)

I-2.Ipayipi lensimbi liphansi futhi i-chrome eqinile ifakwe.

3.Ukwenza ukulungisa ibhalansi, futhi usebenze kahle.

I-4.Ratchet i-reel shaft engaguquki.

5.Inguqulo egcwele yemisele elengayo iyasebenza kumugqa wokulenga ongu-10 mm × 3 mm.

I-6.Ukulayisha nokukhipha ipuleti lokuphrinta, unyawo lokushintsha ukulawulwa kukagesi ukuya phambili nokuhlehla.

2, Irola yokucindezela yokuphrinta

1.I-diameter yangaphandle ingu-¢ 176mm.

I-2.Ipayipi lensimbi liphansi futhi i-chrome eqinile ifakwe.

3.Ukwenza ukulungisa ibhalansi, futhi usebenze kahle.

4.Umshini wokunyathelisa wegebe lokudayela kwegebe lilungiswa ngesandla, ngobubanzi obungu-0-12mm.

3, Ukondla ama-roller aphezulu naphansi

1.Irola ephezulu: Ububanzi bangaphandle yipayipi lensimbi elingu-87mm eliwugqinsi, lifakwe izindandatho ezintathu zokuphakela amaphepha.

2.Irola ephansi: Ububanzi bangaphandle ¢ 112mm ipayipi lensimbi eliwugqinsi, indawo engaphezulu igaywe futhi i-chrome eqinile icwecwe.

3.Igebe legebe lamarola wokuphakela amaphepha lilungiswa mathupha, ngobubanzi obungu-0-12mm.

4. Insimbi ye-anilox roller

1.Ububanzi obungaphandle ngu-¢ 212 ㎜.

2.Ipayipi lensimbi eligaya phezulu, i-anilox ecindezelwe, i-chrome eqinile efakwe.

3.Ukwenza ukulungisa ibhalansi, futhi usebenze kahle.

4.Inombolo ye-mesh ingu-200,220,250,280 ngokwezinketho zakho

5.Ngohlelo lokuphakela ngephepha lwedivayisi yokuphakamisa okuzenzakalelayo ye-pneumatic (ngesikhathi sokuphakelwa kwephepha, i-anilox roller yehla ukuze ithinte ipuleti, futhi lapho ukuphakelwa kwephepha kuma, i-anilox roller iphakama ukuze ihlukane nepuleti).

6.I-Anilox roller ene-wedge - uhlobo lwe-block overrunning clutch, kulula ukuwasha uyinki.

5. I-roller yerabha

1.I-diameter yangaphandle ingu-¢ 195mm.

I-2.I-tube yensimbi ihlanganiswe ne-rubber engaguquki futhi ilinganisela.

I-3.I-Rubber medium high ukugaya okukhethekile, umphumela omuhle wokudlulisa uyinki.

6, Indlela yokulungiswa kwesigaba

1. Ukwakhiwa kwegiya leplanethi.

2.Isigaba sokuphrinta sikagesi wedijithali 360 ° ukulungiswa.(ukusebenza nokuma kungalungiswa)

3.Lungisa ngokuzenzakalelayo indawo evundlile, nebanga eliphelele lokulungiswa elingu-14mm.

7, Ukujikeleza kukayinki

I-1.Iphampu ye-diaphragm ye-pneumatic, ukunikezwa kukayinki ozinzile, ukusebenza okulula nokugcinwa.

2.Isikrini sikayinki, ukungcola kokuhlunga.

3.Ithangi likayinki wePlastiki.

8, Idivayisi yokulungisa isigaba sokuphrinta

1.Isilinda uhlobo lwebhuleki indlela.

2.Lapho umshini uhlukaniswa noma isigaba silungiswa, indlela yebhuleki ikhawulela ukujikeleza komshini futhi igcina iphuzu elimisiwe lendawo yokuqala yegiya.

9, Idivayisi yokulungisa isigaba sokuphrinta

I-1.I-cylinder brake mechanism

2.Uma umshini uhlukaniswa noma isigaba silungiswa, indlela yebhuleki ivimbela ukujikeleza komshini futhi igcina iphuzu elimisiwe langempela lendawo yegiya.

III.Slotting iyunithi

Ummese wokulungisa ishaft eyodwa

- I-Cord-Grip

〖1〗 Ububanzi be-Shaft:¢110㎜ Ubuso bensimbi: buboshiwe, bufakwe i-chrome eqinile, obuzinzile lapho bunyakaza.

〖2〗 Ibhalansi ilungisiwe futhi izinzile ekusebenzeni

〖3〗 Ukudayela okucacile phakathi kwamaroli okuphakelayo: kulungiswe ngesandla, hlela :0~12㎜

- I-Horizontal Adjusting Mechanism Of Slotting Blade Seat

〖1〗 Shaft Diameter:¢154㎜insimbi eqinile, egwetshiwe, egcwele i-chrome eqinile, ezinzile lapho ihamba

〖2〗 Ububanzi be-Slotting: 7㎜

〖3〗 I-slotting blade: enamasondo ensimbi futhi afakwe ngokushisa avela ku-steel alloy futhi abraded ngobulukhuni obukhulu nokugqokeka

〖4〗 I-Double-Edge blade: Ifakwe ngokushisisa nge-alloy yensimbi ne-tart futhi inembile

〖5〗 Isondo le-Crimping, isondo eliqondisayo lephepha, i-Notching blade: ilungiswe nge-PLC, isikrini sokuthinta ukuze sisebenze.

- I-Slotting Phase-Adjusting Mechanism

〖1〗 Yakhelwe ngamagiya eplanethi.

〖2〗 Isigaba sokuphrinta: silungiswa ngo-360° ukuze sisebenze.

4. Isihlalo Sesikhunta Esiphathekayo

1. Isihlalo sobubanzi besikhunta esingaphezulu: 100㎜, isihlalo sobubanzi besikhunta esiphansi:100㎜(nethreyi yerabha).

2..The die hole pouncing can ukwenza ngokuvumelana nesicelo ikhasimende.

5. Iswishi yokulawula

1.Iphaneli yokulawula: inkinobho yokumisa ukuphuma, engalawula kalula uhlelo lokuphakela iphepha kanye nesistimu yokuphrinta, uhlelo lokuphawula

IV.Stacking Department

1, Ingalo yokwamukela iphepha

1.Ukusebenza ngesandla noma okuzenzakalelayo kungakhethwa.

I-2.Iphepha elithola ibhande lokushayela ingalo, lungisa ukuqina ngokuzimela, kungakhathaliseki ukuthi ubude bebhande.

2. Uhlelo lokuphakamisa amanzi ombhede

1.Eqhutshwa yiketanga eliqinile.

2. Ubude be-Stacking: 1600 mm.

3.Umbhede uphakanyiswa futhi wehliswe ngesistimu yokuphakamisa i-hydraulic, egcina umbhede usesimweni esimisiwe futhi ungasheleli.

4.Idivayisi yokuvikela ukuphepha ifakwe ukwenza umbhede netafula kuphakame futhi kuwele ngaphansi kokulawulwa, okuqinisekisa ukuphepha kwabaqhubi.

5.Ibhande lokukhuphuka elishwabana eliyisicaba ukuvimbela amakhadibhodi ukuthi angasheleli.

3. Iphepha lokwamukela indida

1.Iphepha lesenzo somoya elithola isiphithiphithi, lapho ibhodi lephepha linamathiselwe ekuphakameni okunqunywe kusengaphambili, iphepha elithola ipuleti lokusekela liyanwebeka ngokuzenzakalelayo ukuze libambe iphepha.

2. Lungisa ngokuzenzela ukuma kwe-baffle yangemuva.