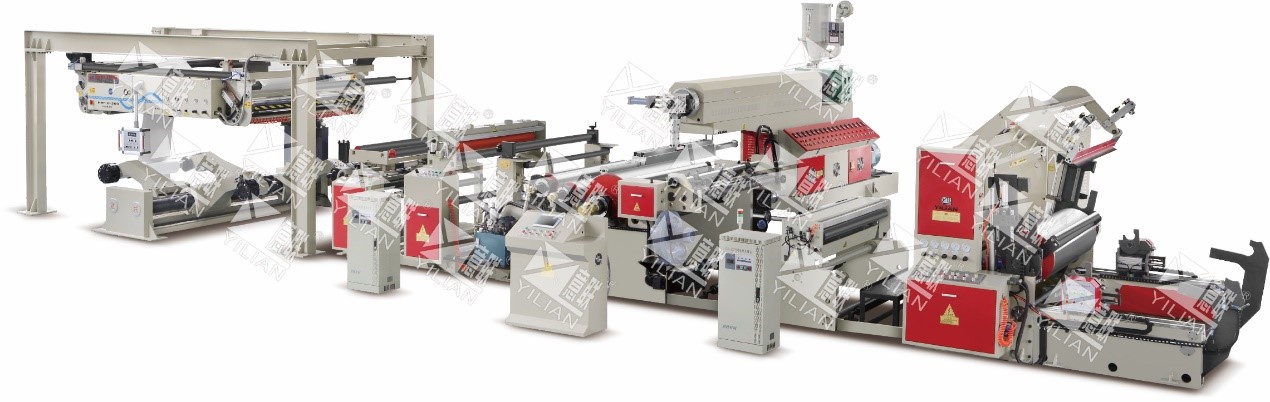

I-WSFM1300C Automatic Paper PE Extrusion Coating Machine

| Faka i-laminating resin | I-LDPE, PP njll |

| Isisekelo sempahla | iphepha (80-400g/m²) |

| Isivinini esikhulu sokusebenza | 300m/min(isivinini sokusebenza sincike kubukhulu bokunamathela, ububanzi) |

| Ububanzi be-coating | 600-1200, ububanzi roller umhlahlandlela: 1300mm |

| Ukuqina kwe-coating | 0.008—0.05mm (Isikulufu esisodwa) |

| Iphutha lokujiya koqweqwe | ≤±5% |

| Ibanga lokusetha i-Auto tension | 3-100kg imajini egcwele |

| Ubuningi be-extruder obukhulu | 250 kg/h |

| I-roller yokupholisa ehlanganisiwe | ∅800×1300 |

| Isikulufa Ububanzi | ∅110mm isilinganiso35:1 |

| I-diameter yokukhulula enkulu | ∅1600mm |

| Ubukhulu bobubanzi bokubuyisela emuva | ∅1600mm |

| Khipha ukhiye wephepha :3″6″ kanye nobubanzi bomgogodla wephepha lokuhlehlisa:3″6″ | |

| I-Extruder idonsa ngama-45kw | |

| Amandla aphelele | cishe 200 kw |

| Isisindo somshini | cishe 39000kg |

| Ubukhulu bangaphandle | 16110 mm×10500 mm × 3800 mm |

| Umbala womzimba womshini | Okumpunga nokubomvu |

1. Hlehlisa ingxenye (nge-PLC, i-servo unwinding)

1.1 Khipha uhlaka

Isakhiwo: Uhlaka lwe-Hydraulic shaft-less unwinding

I-BA series splicer yakha ingxenye ebalulekile yolayini we-lamination futhi ifakwe phezu kwesitendi sokugoqwa ngaphansi kwesakhiwo sebhuloho. Ivumela ukuqhubeka nokusebenza komqulu wephepha okhona uye kumqulu wephepha olandelayo ngaphandle kokumiswa kokukhiqiza.

Ngaphakathi kwamafreyimu aseceleni okuhlanganisa kukhona amakhanda ahlanganisayo angu-2 kanye nesigaba sokusekela esinyakazayo. Ngaphezulu kwawo kukhona ama-nip rolls angu-2.

I-capstan roll, i-reverse idler roll kanye nesistimu yokudansa ephindwe kabili yakha isigaba sokuqongelela amaphepha esikwazi ukuqongelela iphepha elifika ngokuphindwe ka-4 ubude be-splicer.

Umshini usebenza ngephaneli yokusebenza emshinini

Isivinini sokuxhumanisa iphepha I-Max.300m/min

a)lapho amandla ephepha angaphezu kuka-0.45KG/mm, ubuningi. 300m/min.

b)lapho amandla ephepha angaphezu kuka-0.4KG/mm, ubuningi. 250m/min.

c)lapho amandla ephepha angaphezu kuka-0.35KG/mm, ubuningi. 150m/min.;

Ububanzi bephepha

Ubukhulu. 1200mm

Okuncane. 500mm

Isivinini CE-300

Ubukhulu. 300m/min

Idatha ye-pneumatic

Setha i-pressure 6.5 bar

Okuncane. ingcindezi 6 bar

Imodeli CE-300

Amandla angu-3.2kVA, 380VAC/50Hz/20A

Lawula i-voltage 12VDC/24VDC

1.1.1 I-hydraulic shaft spindle spindle spindle ezimele yohlobo lwengalo yesiteshi sokusebenza ephindwe kabili, ngaphandle kwe-air shaft, ukulayishwa kwe-hydraulic, yonga izindleko zokulayisha isakhiwo semishini. Ukushintshanisa okuzenzakalelayo kwe-auto reel ye-AB shaft, ukumosha okuncane kwezinto.

1.1.2 Ubukhulu. Ukuvula ububanzi: ¢1600mm

1.1.3 Ibanga lokusetha i-Auto tension :3—70kg imajini egcwele

1.1.4 ukunemba kokuqina: ± 0.2kg

1.1.5 ingqikithi yephepha:3” 6”

1.1.6 Uhlelo lokulawula ukushuba: uhlobo lwe-shaft lomtshina we-tension by precision potentiometer ukuthola ukungezwani, ukulawulwa okumaphakathi kwe-PLC ehlelekayo

1.1.7 Isistimu yokulawula idrayivu:I-PIH cylinder braking, impendulo yesishumeki esijikelezayo ngokushesha, ukunemba kokulawula i-valve elawula i-loop control evalayo, isilawuli esihlelekayo se-PLC isilawuli esimaphakathi

1.1.8 Ukuhlelwa kwe-tension :Ngokunemba kokusetha kwevalvu elawula ukucindezela

1.2 Ukugcina uhlobo lokukhetha okuzenzakalelayo, idivayisi yokusika

1.2.1 Ukugcina okuqhutshwa isibhafa semotor ye-pneumatic, qinisekisa ukushuba okuzinzile lapho ukha iphepha.

1.2.2 isakhiwo sokusika esihlukene

1.2.3 PLC ibala ngokuzenzakalelayo isivinini esisha sokujikeleza kwe-shaft, futhi ugcine isivinini ngesivinini somugqa omkhulu

1.2.4 Thola i-roller yokucindezela okubalulekile, i-cutter material ephukile .tension control change, ukusetha kabusha konke kungaqeda ngokuzenzakalelayo

1.2.5 Ukushintsha i-alamu yangaphambili,: ububanzi bomsebenzi lapho ufinyelela ku-150mm., Umshini uzokhala

1.3 Ukulawula ukulungisa: i-photoelectric putter rectifying system (isakhiwo se-bst)

2. Corona (Yilian customized)

Amandla okwelapha iCorona :20 kw

3. Iyunithi ye-Hydraulic lamination:

3.1 Ama-roller amathathu anesakhiwo esiyinhlanganisela, i-back press roller, angenza amandla ebhere elihlanganisiwe aqine, aqine.

3.2 Ukuhlutshwa kwerola yerabha ye-silicon: umkhiqizo oyinhlanganisela kulula ukuwulunguza kurola opholile, iHydraulic ingacindezela ngokuqinile.

3.3 Isakhiwo sokucaba ifilimu egobile,: ingenza ifilimu isetshenziswe ngokushesha

3.4 I-Compound feed material adjust roller inganqoba ukujiya kwefilimu ngokungalingani nokunye ubuthakathaka

3.5 I-high pressure blower imunca unqenqema lwe-scrap ngokushesha.

3.6 Irola lokusika eliyinhlanganisela

3.7 I-Compound roller ishayelwa yinjini ngokuncika

I-3.8 I-Compound roller driven motor ilawulwa isilawuli samafrikhwensi sase-Japan

Ukucaciswa:

(1) i-roller yenhlanganisela:¢ 800 × 1300mm 1pcs

(2) irabha roller: ¢ 260 × 1300mm 1pcs

(3) cindezela i-roller:¢ 300 × 1300 mm 1pcs

(4) ukuhlanganisa isilinda kawoyela:¢63 × 150 2pcs

(5) hlubula i-roller:¢130 × 1300 1pcs

(6) 11KWmotor (SHANGHAI) 1set

(7) 11KW Frequency converter (JAPAN YASKAWA)

(8) zungezisa isixhumi: (2.5"2 1.25"4)

4. I-Extruder (ukulungiswa kobude obuzenzakalelayo)

4.1 Screw diameter:¢ 110,I-Extruder Max cishe:250kg/h (ubuchwepheshe baseJapane)

4.2 T-die (Taiwan GMA)

4.2.1 Ububanzi besikhunta: 1400mm

4.2.2 Isikhunta ububanzi obusebenzayo:500-1200mm

4.2.3 Igebe lezindebe zokubunjwa: 0.8mm, ukujiya kokumboza: 0.008—0.05mm

4.2.4 Iphutha lokujiya kokunamathela:≤±5%

4.2.5 Ishubhu yokushisisa kagesi ngaphakathi kokushisisa, ukushisa okuphezulu ngempumelelo, izinga lokushisa likhuphuka ngokushesha

4.2.6 Iphaseji elivaleke ngokuphelele, Ukulungiswa kobubanzi bokugxumeka

4.3 Amadivayisi enethiwekhi ashintsha ngokushesha

4.4 Ukuhamba phambili nangemuva, kungaziphakamisa ngokuzenzakalelayo iTrolley, phakamisa ibanga:0-100mm

4.5 Isikhunta 7 izindawo zokulawula izinga lokushisa. Isikulufa sokulawula izinga lokushisa kwesigaba sesi-8. isixhumi sokulawula izinga lokushisa kwendawo engu-2 sisebenzisa amayunithi okushisa e-infrared.

4.6 Ibhokisi legiya elikhulu Lokunciphisa amandla, IZINYO ELIQINILE (Guo tai guo mao)

4.7 Isilawuli sezinga lokushisa esizenzakalelayo sokulawula izinga lokushisa

Izingxenye eziyinhloko:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW isiguquli sefrikhwensi (JAPAN YASKAWA)

(3) Digital lokushisa isilawuli 18pcs

(4) 1.5KW umshini wokuhamba

5.Idivayisi yokunquma ummese oyindilinga we-Pneumatic

5.1 Idivaysi yokulungisa i-trapezoidal screw transverse, shintsha ububanzi bokusika bephepha

5.2 I-Pneumatic Pressure cutter

5.3 5.5kw high pressure onqenqemeni ukumunca

6.Iyunithi Yokubuyisela emuva :Isakhiwo se-3D esindayo somsebenzi

6.1 Uhlaka Lokubuyisela emuva:

6.1.1 Iziteshi zikagesi zohlobo lwe-Friction double umshini wokubuyisela emuva, ukusika okuzenzakalelayo okunesivinini esikhulu kanye nokukha impahla eqediwe, ukuthulula okuzenzakalelayo.

6.1.2 Ubukhulu. ukuhlehlisa ububanzi:¢ 1600 mm

6.1.3 isivinini sokugoqa:1r/min

6.1.4 ukungezwani: 3-70kg

6.1.5 Ukunemba kweTension:± 0.2kg

6.1.6 ingqikithi yephepha: 3" 6"

6.1.7 Uhlelo Lokulawula Ukuqina: I-cylinder cushion intanta isakhiwo sohlobo lwerola elintantayo, i-tension itholwa nge-precision potentiometer, futhi isilawuli esihlelekayo se-PLC silawula ukungezwani phakathi nendawo. (Japan SMC low friction cylinder) 1 isethi

6.1.8 Uhlelo Lokulawula Idrayivu: 11KW idrayivu yemoto, impendulo yesivinini se-rotary encoder, isilawuli se-Senlan AC inverter dual closed-loop control, isilawuli esihlelekayo se-PLC esiphakathi nendawo. 1 isethi

6.1.9 Isilungiselelo Sokushuba Kanjalo: Ukusetha Isilawuli Sokucindezela Okuqondile (Japan SMC)

6.1.10 Ukulungiselelwa kwe-Taper tension: kusethwe ngokungafanele isikrini sekhompyutha, isilawuli se-PLC, ukuguqulwa ngesilinganiso sikagesi/somoya (i-Japan SMC)

6.2 Idivayisi Yokudla Okuzenzakalelayo Nokusika

6.2.1 Ama-Splicing Support Rollers alawulwa yi-PLC ukushayela injini ukubamba impahla kude nerola yokuhlikihla.

6.2.2 Indlela Yokusika Ezizimele Esebenzisa Amanzi

6.2.3 PLC ukubala okuzenzakalelayo kwenqubo yokukha, ukushintshwa kwevolumu kuqedwa ngokhiye

6.2.4 Umsebenzi Wokusekela Irola, Impahla Esikayo, Ukusetha Kabusha, njll. Kuqedwe Ngokuzenzakalelayo

6.2.5 Imininingwane

(1) I-Friction roller: ¢700x1300mm ibha engu-1

(2) Injini evunguzayo: 11KW (Shanghai Lichao) isethi engu-1

(3) Ibhokisi legiya elehlisela phansi: isinciphisi segiya le-helical eliqinile (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 isethi

(5) Ibhokisi legiya le-roller lokusekela: Isethi engu-1 yamandla

(6) Isinciphisi sesivinini: izinyo eliqinile 1 isethi yamandla

(7) Isinciphisi sesivinini esiginqikayo: Isethi yamandla e-1

(8) Ukushaja isiteshi se-hydraulic

7.I-Auto air shaft puller

8.Isigaba seDrayivu

8.1 Injini eyinhloko, ibhande lokudlulisela lithatha ibhande elihambisanayo

8.2 Injini ehlanganisayo, ebuyisela emuva futhi eqaqa: Ibhande lokushayela lithatha igiya le-arc, iketango kanye nokuhanjiswa kwebhande elivumelanayo

8.3 Ibhokisi legiya lokushayela eliyinhloko: Igiya le-helical elicwiliswe ngamafutha, Isakhiwo sokuhambisa igiya le-helical

9.Iyunithi yokulawula

Ikhabethe likagesi elizimele, isilawuli esimaphakathi, indawo eyinhlanganisela enokusebenza kwekhabhinethi yokulawula okumaphakathi. Isistimu yokuzenzakalela komshini isebenzisa isethi yedivayisi ye-PLC (i-hollsys) enekhono eliphezulu lokucubungula, kanye namasignali engxoxo yomshini womuntu kusetshenziswa ukuxhumana kwenethiwekhi phakathi kwesixhumi esibonakalayo. I-PLC, iyunithi ye-extrusion, isixhumi esibonakalayo sengxoxo yomshini womuntu phakathi kwesistimu yokushayela futhi akha uhlelo oludidiyelwe lokulawula oluzenzakalelayo. Kunoma imaphi amapharamitha angasethwa, ngokubala okuzenzakalelayo, inkumbulo, ukutholwa, i-alamu, njll. Ingabe ukungezwani kwedivayisi yesibonisi esibonakalayo, isivinini, ukujiya kokumboza, isivinini kanye nesimo sokusebenza esihlukile.

10. abanye

11.1 I-Roller Yomhlahlandlela: I-anodization eqinile ye-aluminium alloy guide roll, inqubo yokunyakaza

11.2 Imishini kagesi ephansi ye-France Schneider, i-omron Japan, njll.

11.izingxenye brand

11.1 PLC (Beijing Hollysys)

11.2 Isikrini sokuthinta (TAIWAN)

11.3 i-frequency converter: Japan Yaskawa

11.4 Injini eyinhloko: SHANGHAI

11.5 isilinda esiphansi sokungqubuzana (i-Japan SMC)

11.6 AC CONTACTOR (Schneider)

11.7 inkinobho (Schneider)

11. I-Static mixer (i-Taiwan)

11.9 ivalve elawula umfutho we-cylinder (Taiwan)

11.10 I-valve yokushintshanisa kazibuthe (i-Taiwan)

11.11 ukunemba kwevalvu elawula ingcindezi (SMC)

12.Ikhasimende lizihlinzeka ngezinsiza

12.1 Indawo yezinsiza kanye nesisekelo

12.2 Ukuhlinzekwa kwezinsiza zeKhabhinethi kagesi yoMshini

12.3 Ukuhlinzekwa kwamanzi ezinsizeni zomshini ngaphakathi nangaphandle kwesango (umthengi ulungisa isiqandisi samanzi)

12.4 Ukuhlinzekwa kwegesi emshinini ofakwe ngaphakathi nangaphandle kwesisu

12.5 Ipayipi lokukhipha umoya nefeni

12.6 Qoqa, ulayishe futhi uthulule isisekelo sempahla ithuluzi eliqediwe

12.7 Ezinye izinsiza ezingabaliwe kwinkontileka

13. Uhlu lwezingxenye eziyisipele:

| Cha. | Igama | Ukucaciswa. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Isilawuli sezinga lokushisa | u-Omron |

| 3 | I-valve ye-micro-regulating | 4V210-08 |

| 4 | I-valve ye-micro-regulating | 4V310-10 |

| 5 | i-proximity switch | 1750 |

| 6 | Ukudluliselwa okuqinile | 150A kanye 75A |

| 7 | ukushintsha ukuhamba | 8108 |

| 10 | Iyunithi yokushisa | ϕ90*150mm,700W |

| 11 | Iyunithi yokushisa | ϕ350*100mm, 1.7KW |

| 12 | Iyunithi yokushisa | 242*218mm, 1.7KW |

| 13 | Iyunithi yokushisa | 218*218mm, 1KW |

| 14 | Iyunithi yokushisa | 218*120mm,800W |

| 15 | Inkinobho ye-Schneider | ZB2BWM51C/41C/31C |

| 16 | iqhude lomoya | |

| 17 | Itheyiphu yokushisa ephezulu | 50mm*33m |

| 18 | i-tellon tape | |

| 19 | Ikhava ye-Corona roller | 200*1300mm |

| 20 | Ishidi lethusi | |

| 21 | isihlungi sesikrini | |

| 22 | Zungezisa imifantu | 150*80*2.5 |

| 23 | isixhumi se-pneumatic | |

| 24 | isibhamu somoya | |

| 25 | amanzi ahlangene | 80A kanye 40A |

| 27 | izikulufu nabanye | |

| 28 | iketango lokudonsa | |

| 29 | ibhokisi lamathuluzi |

Izingxenye eziyinhloko nesithombe:

I-Unwinder(Auto splicer) → isiqondiso sewebhu → I-Corona treater → I-Extrusion kanye nengxenye yokuhlanganisa I-Edge Trimming → Ukuhlehlisa