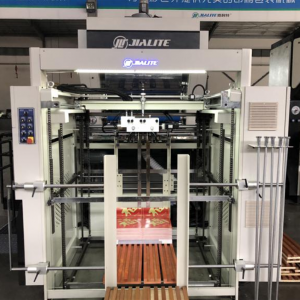

I-NFM-H1080 Umshini Wokucwenga Okuzenzakalelayo Oqondile

| Imodeli | I-FM-H |

| I-FM-1080-Ubukhulu. usayizi wephepha-mm | 1080×1100 |

| I-FM-1080-Miz. usayizi wephepha-mm | 360×290 |

| Isivinini-m/min | 10-90 |

| Ubukhulu bephepha-g/m2 (ukusika ummese oyindilinga) | 80-500 |

| Ubukhulu bephepha-g/m2 (ukusika ummese oshisayo) | ≥115 amagremu |

| Ukunemba kokugqagqana-mm | ≤±2 |

| Ubukhulu befilimu (i-micrometer evamile) | 10/12/15 |

| Ugqinsi oluvamile lweglue-g/m2 | 4-10 |

| Ugqinsi lwefilimu yokunamathisela ngaphambili-g/m2 | 1005,1006,1206 |

| Ubude bokudla okungayeki-mm | 1150 |

| Ubude bephepha lomqoqi (kuhlanganise nephalethi)-mm | 1050 |

| Powe | 380V-50Hz-3Pamandla okushisa:20kwamandla okusebenzaamandla: 35-45kwAmandla aphelele akhona:75kw Isiphazamisi sesifunda: 160A |

| working pressure-Mpa | 15 |

| Iphampu ye-vacuum | 80psiAmandla: 3kw |

| I-air compressor | Ukugeleza kwevolumu: 1.0m3/min,Ingcindezi elinganiselwe: 0.8mpaAmandla:5.5kwIpayipi lokungenaDia.8mm (phakamisa ukuthi usebenzise umthombo womoya Ophakathi) |

| Ukujiya kwekhebula-mm2 | 25 |

| Isisindo | 9800kgs |

| Ubukhulu (isakhiwo) | 8400*2630*3000mm |

| Iyalayisha | 40HQ |

IPHITHI LOKUDLA

1. I-Servo Motor Feeder, amasucker angu-4 okuphakanyiswa kanye nama-suckers angu-4 okuhambisa isakhiwo. I-Max Speed 12000 amashidi/h.

2. Ithebula lokuphakela iphepha linokuvikelwa okungaphezu komkhawulo naphansi.

3. Ukuphakama kokuphakelayo okunganqamuki kungafinyelela ku-1150mm, idivayisi yokupakisha ngaphambili, ukuphakela okungayeki.

4. Ukulungiswa okuhlakaniphile kwezindawo zangaphambili nezangemuva ze-Feeder, vele ufake idatha yomkhiqizo kuphaneli yokulawula

5. BECKER VACUUM PUMP

ITHEBULA LOKUDLULISA NOKUHLANGABEZANA

1.Ithebula lokudlulisa lamukela ibhodi likathayela elenziwe ngezifiso lensimbi engagqwali.

2.Isondo lebhulashi kanye nesondo lokucindezela irabha lihamba kahle.

I-3.Servo motor ukugqagqana, ngcono ukunemba ethangeni, iphutha≤±2mm.

ISIKHIPHA UTHULI KANYE NE-WINDOW LAMINATING(NGOKUZITHANDELA) Imbobo yokususa uthuli yefasitela nokomisa

Idivayisi yokukhipha i-powder yokushisa eyodwa (uyazikhethela) inesakhiwo esihlangene, isiteji sinomsebenzi wokudonsa ukuze kuqinisekiswe ukuthi iphepha ngokusebenzisa idivayisi yokususa impushana ayishintshi.

Isikhiphi sothuli singasusa uthuli ebusweni bephepha ngemva kokunyathelisa ukuze sigweme amabala amhlophe ngemva kokuba iphepha limboziwe.

Ngokusho kwesidingo samakhasimende ukufaka i-inkjet idivayisi etafuleni lokususa uthuli, umshini we-inkjet kanye nomshini wokulathisa kwenziwa ngomshini owodwa.

Ithebula le-inkjet lingakhethwa ngokuzimela.

I-Window coating (uyazikhethela), eyakhiwe ngekhanda lomshini wokunamathisela kanye nohhavini we-infrared. Ngemuva kokuthi iphepha linamathele, lihlanganiswe nefilimu ngemva kokudlula kuhhavini le-infrared.

Iyunithi yokomisa enama-pcs angu-12 IR ukukhanya, Amandla okushisa aphelele 14.4kw.

Uma ungasebenzisi imikhiqizo yewindi, le ngxenye ingasetshenziswa njengethuluzi lokususa impushana yamanzi.

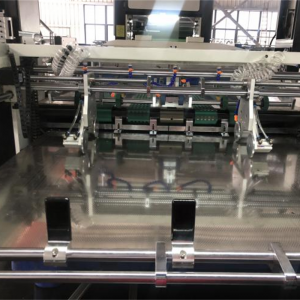

I-LAMINATOR HOST

Ububanzi be-roller yokomisa bukhuphuke baba ngu-1000mm, kusetshenziswa uhlelo lokushisisa ngogesi.

Irola yomshini wokushisisa ithatha isistimu yokushisisa ehlukene, esebenza kahle futhi eyonga amandla.

Ukucindezela okukhulu kwe-press roller ngu-12T.

I-Glue roller ne-metering roller iqhutshwa ama-motor azimele amabili, okwenza ukulungisa kube lula kakhulu.

Uhlelo lwe-Gluing Teflon inqubo yokwelashwa, kulula ukuyihlanza futhi ayinamatheli.

Idivayisi yokuvala ifilimu kadoti.

IPHITHI LOKUSIKA

I-paper cutter ifakwe isilawuli se-tension kanye ne-anti-curl device ukuqinisekisa ukuthi iphepha liyisicaba futhi aligoqekile.

Ingxenye yokusika iphepha iqukethe isondo lokugaya, ummese wediski kanye nommese oshisayo wokusika, ukuhlangabezana nezidingo zamakhasimende zokusika amafilimu ezinto ezihlukahlukene.

I-roller bounce ilawulwa yi-motor ezimele, futhi iphepha lingahlukaniswa ngokusebenzisa umehluko wejubane.

Ummese oshisayo onengcindezi ephansi Ukushisa okuqondile nokusika ngaphandle kwefilimu yomsila, ukuthola ukushuba kwephepha nokusika, kunembile futhi kusebenza kahle.

UMQOQI ONGAMI

Ubude bomqoqi ongami bungafinyelela ku-1050mm. Uma isitaki sesicishe sigcwele, ibhande lokuhambisa lizonwebeka ngokuzenzakalelayo ukuze lamukele iphepha. Inkundla yomqoqi izokwehla. Ngemuva kokuthi kushintshwe ithreyi, inkundla izophinda isetshenziswe futhi iqedele umqoqi ongami.

Yamukela isakhiwo sokuhlunga amaphepha omoya ukuze uqinisekise ukuhlanzeka kwephepha futhi wenze kube lula inqubo elandelayo, ngesondo lokunciphisa ukuvimbela iphepha ukuthi lingonakali ngenxa yokushesha ukushaya i-baffle.

Ukubala iso likagesi, inani lephepha eligijima liboniswa esikrinini sokubonisa emshinini wokuthatha, ongasulwa futhi uqoqwe.

Iso likagesi lokungeniswa, lizwa ubude bephepha, uma ubude bephepha bushintsha, ibhande lizosheshisa, futhi i-baffle yomshini wokuthatha izogumbuqela futhi iphakamise iphepha.

Umphakamisi wefilimu

Izingxenye ezisele