I-GUOWANG C106 I-AUTOMATIC DIE-CUTTER NGAPHANDLE KOKUKHIPHA

Ikhanda lesiphakeli sekhwalithi ephezulu

Isistimu yomugqa ophakathi

I-Pneumatic lock die jaha

Ukuphakelwa okunganqamuki nokulethwa

7500Amashidi/H

Umfutho we-Max.300T

Isikrini sokuthinta kabili ukuze usebenze kalula

I-HT500-7 i-ductile cast iron iron

I-FEEDER HEAD Isiphakeli sekhwalithi ephezulu, i-sucker emi-4 kanye nesidluliseli esi-4

I-FEEDER Idivayisi ye-Pre-pile, I-Non-stop feeding Max. Ukuphakama kwenqwaba 1600mm

AIR PUMP German BECKER

ITHEBULA LOKUDLA I-Nitta idlulisa ibhande lensimbi engagqwali eyehlelayo ithebula lokudlulisa

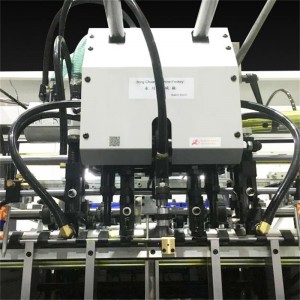

I-STRIPPING SECTION Uhlelo lomugqa ophakathi nendawo Ukuphakamisa ukujaha omoya

ISIGCAWU ESOKUSEKA I-Servo motor evela e-Japan FUJI Ingcindezi ingalungiswa kusikrini esithintwayo esingu-15”, ilungise ukubekezelela ifinyelele ku-0.01mm Max.300T

I-LED TOUCH SCREEN MONITOR ●15” incazelo ephezulu yesikrini sokuthinta se-LED , u-opharetha angakwazi ukubona zonke izilungiselelo endaweni ehlukile, anciphise isikhathi sokushintsha umsebenzi futhi athuthukise ukusebenza kahle kokusebenza.

UHLELO LOKULUBISA Isistimu yokugcoba ezenzakalelayo elawulwa yikhompyutha Ukunakekela okulula

ISIGABA SOKUFA ESIKHATHINI Uhlelo lomugqa ophakathi nendawo Isikhiya somoya sokujaha ukufa okungaphezulu nangaphansi Shintsha ukuze ubone ukuthi amapuleti akhiyelwe endaweni efanele.

UKUDILIVA Max. Ubude benqwaba 1350mm Ukulethwa okunganqamuki

Isiphakeli sekhwalithi ephezulu esinama-suckers angu-4 okuphakamisa iphepha kanye nama-suckers angu-4 ephepha lokudlulisela phambili siqinisekisa iphepha lokuphakela elizinzile nelisheshayo. Ubude kanye ne-engeli yama-suckers kulungiseka kalula ukuze kugcinwe amashidi eqonde ngokuphelele.

Umtshina wamashidi amashidi amabili, idivayisi ebambezeleka ngamashidi, isiphephetha-moya esilungisekayo siqinisekisa ukuthi amashidi adluliselwa etafuleni lebhande kancane kancane nangokunembile.

Iphampu ye-vacuum ivela ku-German Becker.

Ukulungiswa kwenqwaba endaweni ephambanayo kulawulwa yinjini ukuze kuphakelwe amashidi okunembile.

Isistimu yokulayisha ngaphambilini, ukudla okungayeki, inqwaba ephezulu (Ubude benqwaba bufika ku-1600mm).

Izinqwaba eziphelele zingakhiwa kuma-pallets asebenza kumareyili wohlelo lokulayisha kuqala. Lokhu kwenza umnikelo obalulekile ekukhiqizeni okushelelayo futhi kuvumela opharetha ukuthi ahambise inqwaba elungisiwe iye kusiphakeli ngokunembile nangokufanele.

I-Single position engagement i-pneumatic operating mechanical clutch iqinisekisa ukuthi ishidi lokuqala ngemva kokuqalwa kabusha komshini njalo lifakwa ezindlini zangaphambili ukuze kube lula, ukonga isikhathi nokonga impahla.

Izinhlangothi ezibekwe eceleni zingashintshwa ngokuqondile phakathi kwemodi yokudonsa nokusunduza ezinhlangothini zombili zomshini ngokumane uphendule ibhawodi ngaphandle kokwengeza noma ukususa izingxenye. Lokhu kunikeza ukuguquguquka kokucubungula inhlobonhlobo yezinto: kungakhathaliseki ukuthi amamaki erejista angakwesobunxele noma kwesokudla seshidi.

Izihlalo ezisemaceleni nezingaphambili zinezinzwa ezinembile, ezikwazi ukubona umbala omnyama neshidi lepulasitiki. Ukuzwela kuyalungiseka.

Izinzwa zamehlo ezinesistimu yokuma okuzenzakalelayo etafuleni lokuphakelayo zikuvumela ukuthi uthuthukise ukuqapha kwesistimu- ukuze uthole ukulawulwa kwekhwalithi okuphelele phezu kwawo wonke ububanzi beshidi kanye nokujama kwephepha.

Iphaneli yokusebenza yengxenye yokuphakela kulula ukulawula inqubo yokuphakela ngesibonisi se-LED.

Izilawuli ezihlukene zokushayela zenqwaba enkulu nenqwaba eyisizayo

I-PLC nekhamera ye-elekthronikhi yokulawula isikhathi

Idivayisi ye-Anti-isithiyo ingagwema ukulimala komshini.

I-Swiss Rapplon idlulisa ibhande le-feeder futhi isivinini siyashintshwa

Isistimu yokukhiya i-pneumatic lock-up yenza kube lula ukuvala nokukhululwa kwe-cutting chase kanye nepuleti lokusika.

Ipuleti lokusika eliphakamisa umoya ukuze kube lula ukungena nokuphuma.

Uhlelo lwe-Centerline ekuxosheni ukufa ngokulungiswa kwe-transversal micro luqinisekisa ukubhaliswa okunembile okuholela ekushintsheni okusheshayo komsebenzi.

Ukuma okunembile kwe-Cutting chase elawulwa yizinzwa ezibonakalayo ezinembayo ezinedivayisi yokuhlola ezenzakalelayo

Ukunciphisa i-chase turnover device

Siemens motor main elawulwa Schneider inverter.

Ukulungiswa okuncane kwamandla okusika (ukunemba kokucindezela kungafika ku-0.01mm wesishumeki, Max. ingcindezi yokusika ingafika kumathani angama-300) ngegiya lezikelemu elishayelwa yi-servo motor futhi lilawuleke kalula ngesikrini sokuthinta esingu-15 intshi.

I-Crankshaft yenziwe ngensimbi engu-40Cr.

I-HT300 ductile iron yamafreyimu omshini namapuleti

Amasethi angu-7 ama-gripper bar anama-grippers enziwe nge-alloy ye-aluminium engasindi futhi eqinile enejazi eliqinile ne-anodized finish iqinisekisa ukubhaliswa kwephepha okunembile nokungashintshi.

Ibha yokubamba eklanywe ngendlela ehlukile ayidingi sikhala sokunxeshezelwa ukuze kuqinisekiswe ukubhaliswa okunembile kwephepha

I-Renold chain yekhwalithi ephezulu yase-England enokwelashwa okwandisiwe ngaphambilini iqinisekisa ukuzinza nokunemba ngokuhamba kwesikhathi.

Isistimu yokushayela ye-high pressure index yokulawula ukubeka indawo yebha

Idivayisi yokuvikela ukulayisha ngokweqile ene-torque limiter idala izinga eliphezulu lokuphepha ku-opharetha nomshini.

Ukuthambisa okuzenzakalelayo nesistimu yokupholisa yokushayela okuyinhloko kanye nokugcotshwa okuzenzakalelayo kweketango elikhulu.

Cukwakhekas

————————————————————————————————————————————————— ——————————————————————————————

IBHOKISI LESIHLOKO SE-TAIWANI-USA Synchronical BeltSIEMENS MOTOR

UK Renold ChainI-GRIPPER YASEJAPANEIphampu ye-Becker

————————————————————————————————————————————————— ——————————————————————————————

I-DIEBOARD& STRIPPING BOARD IZINGA

UKUHLELWA KWAphansi

UHLELO LWESIZA

————————————————————————————————————————————————— ——————————————————————————————

Iyunithi Yokulethwa

Ibhulashi lokubhuleka elilungisekayo elilawulwa yimoto ye-AC lisiza ukukhulula iphepha ku-gripper nokunqwabelanisa iphepha ngesivinini esiphezulu nokuqondanisa okuphelele.

Ukuphakama kwenqwaba yokulethwa kufika ku-1050mm.

Amadivaysi kagesi wezithombe avimbela ukwenyuka nokwehla ngokweqile kwenqwaba yamaphepha okulethwa

Inqwaba ingabalwa ngenzwa ye-optical (ejwayelekile).

Umshini wonke ungalungiswa nge-touch monitor engu-10.4 inch ohlangothini olungemuva

I-rack yokuthumela eyisiza ilungiselelwe ukulethwa okunganqamuki.

Izingxenye zikagesi

Izitholi zikagesi, ama-micro switched namaseli e-photoelectric alawulwa yi-PLC kuwo wonke umshini

I-Omron Electronic cam switch kanye nesishumeki

Wonke umsebenzi omkhulu ungenziwa nge-touch monitor engu-15 no-10.4 inch.

Ukudluliselwa kokuphepha kwe-PILZ njengokujwayelekile kuqinisekisa izinga eliphezulu lokuphepha.

Iswishi yangaphakathi yokukhiya igcwalisa imfuneko ye-CE.

Ifaka izingxenye zikagesi ezihlanganisa i-Moeller, i-Omron, i-Schneider relay, i-AC contactor ne-air breaker ukuqinisekisa ukuzinza ngokuhamba kwesikhathi.

Ukuboniswa kwephutha okuzenzakalelayo nokuzihlola wena.

Iidatha yokumisa

————————————————————————————————————————————————— ——————————————————————————————

Okuyinhlokoimpahla

————————————————————————————————————————————————— ——————————————————————————————

Ikhadibhodi Lephepha Ibhodi eliqinile eliqinile

Amapulasitiki angaqinile Ifayela lephepha lebhodi likathayela

————————————————————————————————————————————————— ——————————————————————————————

Amasampula ohlelo lokusebenza