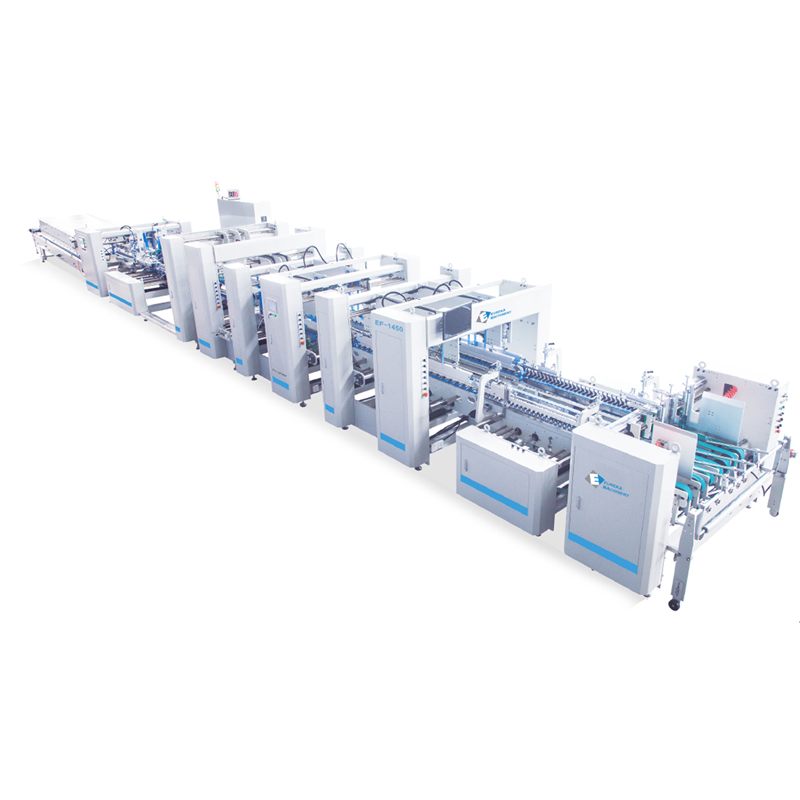

Uchungechunge lwe-EF ifomethi enkulu (1200-3200) I-Automatic Folder Gluer

1) Isigaba sokudla:

I-Folder gluer Isigaba sokuphakelayo siqhutshwa injini ye-AC ezimele enesilawuli, amabhande anwetshiwe, ama-knurl roller nesidlidlizi ukuze kulungiswe isivinini esibushelelezi nesinembile.Amabhodi ensimbi awugqinsi kwesokunxele nakwesokudla anganyakaziswa kalula ngokuya ngobubanzi bephepha;ama-feeding blades amathathu angalungisa usayizi wokuphakela ngokuya ngobude bephepha.Amabhande okumunca ngepompo ye-vacuum ngokubambisana ne-motor, aqinisekisa ukuphakelwa okuqhubekayo nokuzinzile.Ukuphakama kwe-stacking kufika ku-400mm.Ukudlidliza Kungasebenza ngesilawuli esikude kunoma iyiphi indawo yomshini.

2) Isigaba sokuqondanisa uhlangothi lwephepha:

Ingxenye yokuqondanisa ye-gluer yefolda yisakhiwo esinezinkampani ezintathu, sisebenzisa indlela yokuqondisa ohlangothini, siqondisa iphepha endaweni enembile ngokugijima okuzinzile.

3)Isigaba Sokudala (*Inketho)

Isigaba samaphuzu ashayelwa ngokuzimela, esikhwezwa ngemva kwesigaba sokuqondanisa, ngaphambi kokugoqwa, ukuze sijulise imigqa yamaphuzu engashoni futhi ithuthukise ikhwalithi yokugoqa kanye ne-gluing.

4) Isigaba sokugoqa ngaphambili (*PC)

Umklamo okhethekile ungagoqa ngaphambili umugqa wokuqala wokugoqa ku-180 degrees kanye nomugqa wesithathu ku-135 degrees ongenza ibhokisi livuleke kalula ku-gluer yethu yefolda.

5) Isigaba esingezansi se-crash lock:

Ingxenye engezansi ye-Crasg lock yochungechunge lwethu lwe-EF lokugoqa umshini wokunamathisela uyisakhiwo esithwala ezintathu, esinokudluliselwa kwebhande eliphezulu, amabhande aphansi abanzi, siqinisekisa ukuthuthwa kwephepha okuzinzile nokushelelayo.Amadivayisi we-hook aqediwe anezesekeli ukuze alingane namabhokisi ahlukahlukene avamile nangajwayelekile.Izithwali zamabhande angaphezulu zingaphakanyiswa ngomshini womoya ukuze kufakwe izinto eziwugqinsi.

Imishini yokunamathisela ephansi (ngakwesobunxele nakwesokudla) yomthamo omkhulu, inani leglue eliguquguqukayo elinamasondo ahlukahlukene okujiya, ukugcinwa okulula.

6)4/6 ingxenye yekhona(*PCW):

Isistimu yokugoqa ekhoneni engu-4/6 enobuchwepheshe be-servo-motor obuhlakaniphile.Ivumela ukugoqa okunembile kwawo wonke ama-flap angemuva ngokusebenzisa izingwegwe ezifakwe kumashafu amabili azimele alawulwa nge-elekthronikhi.

Isistimu ye-Servo nezingxenye zebhokisi lekhona le-4/6

Isistimu ye-Yasakawa servo enemojula yokunyakaza iqinisekisa impendulo yejubane eliphezulu ukufanisa isicelo sesivinini esikhulu

Isikrini sokuthinta esizimele sisiza ukulungisa futhi senze ukusebenza kube lula ku-gluer yefolda yethu

7) Ukugoqa kokugcina:

Isakhiwo esinezithwali ezintathu, imojula ekhethekile yokugoqa isikhathi eside ukuqinisekisa ukuthi ibhodi lephepha linesikhala esanele.Amabhande okugoqa angaphandle kwesokunxele nakwesokudla ashayelwa izinjini ezizimele ezinejubane eliguquguqukayo lokugoqa okuqondile nokusiza ukugwema “umsila wezinhlanzi” ku-glue yefolda.

8) I-Trombone:

Ukushayela ngokuzimela.Amabhande aphezulu naphansi angahanjiswa phambili nangemuva ukuze kube lula ukulungiswa;Shintsha ngokushesha phakathi kwezindlela ezahlukene zokupakisha;Ukulungiswa kokuqina kwebhande okuzenzakalelayo;Idivayisi yokugijima yokuvala ngokunembile amabhokisi angaphansi kwesikhiya sokuphahlazeka, Ikhawunta ezenzakalelayo ene-kicker noma inkjet ozomaka;I-paper jam detector ifakwe i-pneumatic roller ukuze ucindezele amabhokisi ukuze abe yisimo esifanele.

9) Ukucindezela isigaba sokuthutha:

Ngesakhiwo sokushayela esizimele esiphezulu nesingaphansi, kulula ukulungisa isidluliseli esingaphezulu ukuze silingane ubude bebhokisi.Ibhande elithambile nelibushelelezi ligwema ukunwaya ebhokisini.Ibhande lesipontshi lokuzikhethela ukuqinisa umphumela wokucindezela.Uhlelo lwe-pneumatic luqinisekisa ikhwalithi yokucindezela elinganiselayo futhi ephelele.Isivinini sokuthutha singavunyelaniswa nomshini oyinhloko ukuze ulandelele okuzenzakalelayo ngenzwa yokubona kanye nokulungiswa ngesandla.

Imishini yokunamathisela yefolda ye-EF yochungechunge inemisebenzi eminingi, ikakhulukazi yamaphakheji anosayizi ophakathi wekhadibhodi engu-300g -800g, 1mm-10mm kathayela, E,C,B,A,AB,EB,izinto ezinhlanu zikathayela, zingakhiqiza ukugoqa okungu-2/4. , ngezansi kwesikhiya sokuphahlazeka, ibhokisi lekhona elingu-4/6, ikhathoni elicijile.Isakhiwo semojula yokushayela ehlukanisiwe nesisebenzayo sihlinzeka ngokukhipha okunamandla nokusebenza okulula, okulula, nge-HMI eyingcaca, isilawuli se-PLC, ukuxilonga ku-inthanethi, isilawuli esikude esinemisebenzi eminingi.I-transmission enemoto ezimele idala ukugijima okushelelayo futhi kuthule.Amabhande angaphezulu omphathi ngaphansi kokulawula ukucindezela okuzinzile futhi okulula atholakala ngamadivaysi azimele we-pneumatic.Ifakwe ama-servo motors asebenza kahle kakhulu ezingxenyeni eziqondile, le mishini yochungechunge ingakwazi ukwanelisa izimfuno zokukhiqiza okuzinzile nokusebenza kahle.I-gluer yefolda ikhiqizwa ngokuya ngamazinga we-European CE.

- Idizayini yesakhiwo sokuguquguquka ingathuthukisa imisebenzi yomshini ngokuya ngezidingo zekhasimende.

- Yonke indlela yokushayela i-gluer yefolda isebenzisa ukushayela okuzimele okuvumelanisiwe kwemoto.

- Ifakwe ngokukhethekile ingxenye yokuqondanisa ohlangothini lwephepha.

- Qinisa, unwebe ukushayela ngebhande eliphezulu neliphansi, elifanele amabhokisi kathayela.

- Ukulungiswa kwayo yonke inkampani yenkampani ifakwe injini ukuze isebenze kalula.

- Ukunyakaza kwenkampani yenethiwekhi ephezulu naphansi kusebenzisa isistimu ye-linear guide-rail, ukuze kuqinisekiswe ukunemba kwemishini.

- Idizayini eyenziwe ngumuntu ukuze kufakwe nokusebenza kalula, isipanela esisodwa se-hexagon singalungisa wonke umshini.

- Ukugoqa kokugcina, izigaba ze-trombone ezinamamotho ezimele ukuze zilungiswe, kanye nesigaba sokuthutha esicindezelayo esinomshini we-squaring, kungagwema ngempumelelo “umsila wezinhlanzi” wemikhiqizo eboshiwe.

- Ukucindezela isigaba sokuthutha kusebenzisa isistimu yamasilinda womoya, kulula ukulungisa ukucindezela, futhi kwenze imikhiqizo inganamathela kahle.

- Isikrini sokuthinta, i-HMI eyingcaca, isilawuli esikude esinemisebenzi eminingi ukuze sisebenze kalula.

A.Idatha yobuchwepheshe:

| Ukusebenza/amamodeli | 1200 | 1450 | 1700 | 2100 | 2800 | 3200 |

| Ubukhulu.Usayizi weshidi(mm) | 1200*1300 | 1450*1300 | 1700*1300 | 2100*1300 | 2800*1300 | 3200*1300 |

| Okuncane.Usayizi weshidi(mm) | 380*150 | 420*150 | 520*150 | |||

| Iphepha elisebenzayo | Ikhadibhodi 300g-800g iphepha likathayela F,E,C,B,A,EB,AB | |||||

| Ubukhulu.Isivinini sebhande | 240m/min. | 240m/min | ||||

| Ubude bomshini | 18000 mm | 22000mm | ||||

| Ububanzi bomshini | 1850 mm | 2700 mm | 2900 mm | 3600 mm | 4200 mm | 4600 mm |

| Amandla aphelele | 35KW | 42KW | 45KW | |||

| Ubukhulu.Ukususwa komoya | 0.7m³/min | |||||

| Isisindo esiphelele | 10500kg | 14500kg | 15000kg | 16000kg | 16500kg | 17000kg |

Ibanga losayizi webhokisi eliyisisekelo (mm):

Phawula: ingenza ngendlela oyifisayo amabhokisi osayizi abakhethekile

I-EF:1200/1450/1700/2100/2800/3200

Inothi lemodeli:AC-nengxenye engezansi ye-crash lock;PC-ngokugoqa ngaphambili, izingxenye ezingezansi zokukhiya kokuphahlazeka;PCW--ngokugoqa ngaphambili, i-crash lock, izigaba zebhokisi lekhona elingu-4/6

| Cha. | Uhlu Lokucushwa | Phawula |

| 1 | Idivayisi yebhokisi le-Corner engu-4/6 nge-Yaskawa servo | Okwe-PCW |

| 2 | Ukulungiswa kwezimoto | Okujwayelekile |

| 3 | Iyunithi yokugoqa ngaphambili | OkwePC |

| 4 | Ukulungiswa kwezimoto ngomsebenzi weMemori | Inketho |

| 5 | Iyunithi yokudala ngaphambili | Inketho |

| 6 | Jogger ku-trombone | Okujwayelekile |

| 7 | Isibonisi sephaneli ye-LED | Inketho |

| 8 | Idivayisi yokuguqula i-90 degree | Inketho |

| 9 | Idivayisi ye-pneumatic squaring ku-conveyor | Inketho |

| 10 | Ukucindezela kwe-NSK Up | Inketho |

| 11 | I-glue tank ephezulu | Inketho |

| 12 | I-trombone eshayelwa yi-Servo | Okujwayelekile |

| 13 | Inkampani Mitsubishi PLC | Inketho |

| 14 | Isiguquli | Inketho |

Umshini awufaki uhlelo olubandayo lwe-glue spray system kanye nesistimu yokuhlola, udinga ukukhetha kulaba bahlinzeki, sizokwenza umnikelo ngokuvumelana nenhlanganisela yakho.

| 1 | Isibhamu seglue se-KQ 3 esinephampu yengcindezi ephezulu (1:9) | Inketho |

| 2 | Isibhamu seglue se-KQ 3 esinephampu yengcindezi ephezulu (1:6) | Inketho |

| 3 | Isistimu yokunamathisela ebandayo ye-HHS | Inketho |

| 4 | Ukuhlolwa kwe-Gluing | Inketho |

| 5 | Okunye ukuhlola | Inketho |

| 6 | Isistimu ye-Plasma enezibhamu ezi-3 | Inketho |

| 7 | Ukusetshenziswa kwe-KQ kwelebula yokunamathela | Inketho |

1.

Imikhiqizo yezingxenye eziyinhloko nedatha

| Out Source list | |||

| Igama | Ibhrendi | Indawo yemvelaphi | |

| 1 | Injini eyinhloko | CPG | I-Taiwan |

| 2 | Isiguquli semvamisa | I-JETTECH | USA |

| 3 | HMI | I-PANELMASPER | I-Taiwan |

| 4 | Ibhande lesinyathelo | izwekazi | EJalimane |

| 5 | Ukuzala okuyinhloko | I-NSK/SKF | Japan / Switzerland |

| 6 | Ishaft eyinhloko | I-Taiwan | |

| 7 | Ibhande lokudla | I-NITTA | Japan |

| 8 | Ukuguqula ibhande | I-NITTA | Japan |

| 9 | I-PLC | FATEK | I-Taiwan |

| 10 | Izingxenye zikagesi | Schneider | France |

| 11 | Ithrekhi eqondile | Hiwin | I-Taiwan |

| 12 | umlomo wombhobho | I-Taiwan | |

| 13 | Inzwa kagesi | Sunx | Japan |

|

| |||

| Izesekeli kanye nokucaciswa | Ubuningi | iyunithi | |

| 1 | Ibhokisi lamathuluzi asebenzayo namathuluzi | 1 | setha |

| 2 | i-optical counter | 1 | setha |

| 3 | Ikhawunta yokukhahlela ibhokisi | 1 | setha |

| 4 | Ikhawunta ye-spray | 1 | setha |

| 5 | Iphedi evundlile | 30 | ama-pcs |

| 6 | 15m ithubhu enezingqimba | 1 | hlubula |

| 7 | Isethi yomsebenzi ongaphansi kwe-crash-lock | 6 | setha |

| 8 | Isikhunta sokusebenza esingaphansi kwe-crash-lock | 4 | setha |

| 9 | Imonitha yekhompyutha | 1 | setha |