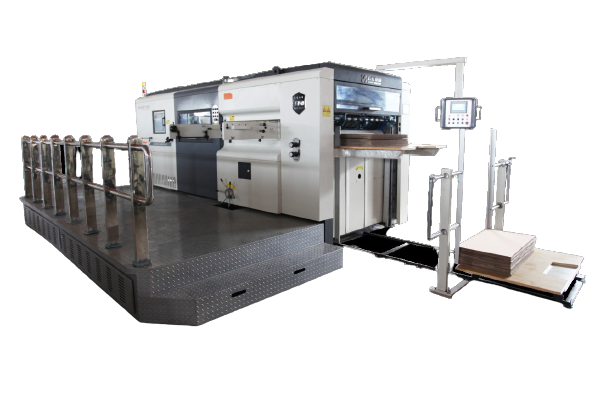

I-Century MWB 1450Q (ngokuhlubula) I-Semi-Auto Flatbed Die Cutter

| Imodeli | I-MWB1450Q |

| Ubukhulu.Usayizi Wephepha | 1480*1080 mm |

| Okuncane.Usayizi Wephepha | 550*480 mm |

| Ubukhulu.Ukusika Usayizi | 1450*1050 mm |

| Ubukhulu.Ukusika Ingcindezi | 300x104N |

| I-Stock Range | Ibhodi likathayela ≤ 9 mm |

| Ukunemba Ukusika Ukufa | ±0.5 mm |

| Ubukhulu.Isivinini sikaMechanical | 4000s/h |

| Ukulungiswa kwengcindezi | ±1 mm |

| Imajini Yangaphambili Encane | 8MM |

| I-Inner Chase Usayizi | 1480*1080 mm |

| Amandla Aphelele | 21KW (ngaphandle kweplatifomu yomsebenzi |

| Ubukhulu bomshini | 7750*4860*2440 mm (Faka inkundla yokusebenza, okondla kwangaphambili) MWB1620Q |

| Ubukhulu bomshini | 5140*2605*2240 mm (Ungafaki iplathifomu yomsebenzi, okondla kwangaphambili) MWB1620Q |

| Isisindo Esiphelele | 19t |

Isigaba Sokudla

√Uhlelo lokuphakela ngezandla olusebenzayo.

√Uhlelo lokuphakamisa inqwaba yeshidi oluzenzakalelayo.

√Umhlahlandlela oseceleni wokumisa isikhungo senqwaba yephepha.

√Isebenza ku-E, B, C, A umtshingo kanye nodonga oluphindwe kabili.

Die Cutting Isigaba

√Indlela yokukhiya i-pneumatic push-chase locking ukuze kuqinisekiswe ukuguqulwa okuphephile nokunobungane kwepuleti lokusika.

√Isistimu yomugqa omaphakathi wokusika okusheshayo ukusetha nokushintsha.

√Uhlelo lwe-nuckle lokucindezela okuphezulu kokusika kuze kufike kumathani angama-400

√Isistimu yokuzithambisa ezenzakalelayo nezimele ukuze isebenze kahle nempilo ende

√Umnyango wokuphepha kanye nedivayisi yesithombe-kagesi ukuze usebenze ngokuphephile.

Isigaba sokukhumula

√Uhlaka oluphezulu lokukhumula lungaphakanyiswa ukuze kukhishwe ukufakela nokushintshwa.

√Isistimu ye-centerline yokusetha ngokushesha ukufa nokushintsha umsebenzi

√Idivayisi yokukhiya uzimele, evumelana nezimo futhi kulula ukuyikhiya futhi ixegise ifa lokukhumula.

√Inzwa yesithombe newindi lokuphepha elihlonyiselwe ukusebenza ngokuphephile.

√I-semi-stripping system ishiya unqenqema lwe-gripper lungakhumuliwe.

Isigaba Sokulethwa

√Abagijimi abaseceleni nabangaphambili ukuze baqinisekise ukupakishwa kahle.

√Uhlelo lokulethwa kwephalethi

√Idivaysi yomphenyi we-Photoelectric yokungena nokusebenza ngokuphepha.

Isigaba Sokulawula Ugesi

√Ubuchwepheshe be-Siemens PLC l bokuqinisekisa ukusebenza okungenazinkinga.

√Izingxenye zikagesi zivela kwa-Siemens, Schneider.

√Zonke izingxenye zikagesi zihlangabezana nezinga le-CE

| Ingxenye yegama | Ibhrendi |

| Ukuzala okuyinhloko | I-NSK |

| Main drive chain | RENOLD |

| I-Frequency Inverter | YASKAWA |

| Izingxenye zikagesi | Siemens/Schneider |

| Isifaki khodi | OMRON |

| Izinzwa zesithombe | Panasonic/Omron |

| Injini eyinhloko | Siemens |

| Ingxenye ye-pneumatic | I-AirTac/SMC |

| I-PLC | Siemens |

| Iphaneli yokuthinta | Siemens |

I-Pre-Feeder

Lesi siphakeli sangaphambili sisiza ukwenza amashidi alandelayo anqwabelene futhi enze ushintsho olusheshayo lwenqwaba yamashidi.Lapho u-opharetha ephakela amashidi kumshini wokusika ukufa, omunye u-opharetha angalungisa enye inqwaba yamashidi ngesikhathi esifanayo.Uma ukuphakelwa kweshidi sekuqediwe, inqwaba yamashidi elungiselelwe ku-feeder yangaphambili ingaphushwa kudivayisi yokuphakamisa inqwaba ngokuzenzakalelayo.Lokhu kuzokonga cishe imizuzu emi-5 yokulungiselela inqwaba yamashidi ngalinye futhi kwandise ukukhiqiza.

Iphaneli yokusebenza enengalo enyakazayo// Siemens Smart line Touch Panel

Isigaba Sokudla

√Ikhamera yokuqapha isimo sesigaba sokulethwa ngaphakathi

√Isistimu yokuphakamisa inqwaba ezenzakalelayo

√Idivayisi yokulungisa yegebe le-infeed phakathi kwamashidi nama-grippers.

√Iwindi lokuphepha nenzwa yesithombe kunikeza isivikelo ku-opharetha nomshini lapho iwindi lokuphepha livuliwe.

√Ukucindezela ipuleti ukuqinisekisa ukuthi amashidi awalokothi adliwe kakhulu ukuze afe

√Abagijimi baseceleni ukuze bagcine inqwaba iphakathi nendawo futhi bathole amashidi alula futhi anembile.

Inzwa yesithombe ukugcina inqwaba iphakama njalo kusesikhathini sokuphakelwa kwamashidi.

Die Cutting Isigaba

√I-Die cutting plate yenziwe nge-65Mn enobulukhuni be-HRC45, ilungele ukusika ukufa.

√Iwindi lokuphepha elihlomele ukuphepha kuka-opharetha nomshini.

√Isistimu yomugqa womugqa wokusika ngokushesha isethi yokufa nokushintsha umsebenzi.

√Ukusika isibambo sokulungiswa kwamandla.Kulula futhi kulula.

Isondo lezikelemu elinomsebenzi wokugaya ngesandla ukuze kuqinisekiswe ukushelela kwendawo yokusika okuqondile.

Automatic self-lubrication system

I-Mono-cast yenzelwe ukudlidliza okuncane uma umshini usebenza.

Iphinifa lokusekela lingashintshwa libe osayizi abahlukahlukene ngosayizi wamakhasi ahlukene.

Isigaba Sokulethwa

√Isistimu yokulethwa kwephalethi engami

√Iphaneli yokusebenza

√Iwindi lokuphepha

√Inzwa yesithombe ihlonyiselwe ukwenza isiqiniseko sokuthi umshini uzoma lapho okuthile kungena emshinini kulesi sigaba.

√Abagijimi baseceleni ukuze baqoqe amashidi ahlanzekile

Iwindi lokubuka lokuhlola iqoqo lamashidi futhi wenze ukulungisa okudingekayo uma kudingeka.

Idivayisi yokulungisa ifomethi yeshidi

Ukulawula Ugesi

CPU Module//Siemens Simatic S7-200

I-Yaskawa Frequency Inverter

Schneider udlulisela, contactors nokunye.

Imigoqo ye-Gripper, eyenziwe nge-aerospace aluminium impahla.

Amasethi amabili engeziwe ama-gripper bar azothunyelwa kanye nomshini njengezingxenye ezisele.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)